| Part Number | ESHKDT11-M01C | Cable Length | 1m~7m |

| Form Factor | SFP+ | Power Consumption | <0.5W |

| Wire AWG | 28~30AWG | Jacket Material | PVC |

| Case Temperature(℃) | 0℃ to +70℃ | Application | 10G Ethernet |

Product Features

Compliant with SFF-8431, 8432 and 8472.

Various choices of wire gauge available from 30 to 24 AWG

Up to 10.3125Gbps data rate per channel

Up to 7m transmission

Operating temperature:-40℃ to +80℃

Single 3.3V power supply

RoHS compliant

Cost-effective copper solution

Lowest total system power solution

Lowest total system EMI solution

Optimized design for Signal Integrity

Product Highlights

Experience unparalleled performance with our 10G SFP+ DAC 1M. Designed for high-speed, low-latency connectivity, this direct attach copper (DAC) cable outshines traditional options like SFP Copper 10G and SFP 10GB CU1m. Unlike standard SFP+ Cable or SFP Cable, our 10G SFP+ DAC 1M offers superior signal integrity and reliability, ensuring seamless data transmission over short distances. Engineered specifically for 10 Gigabit Ethernet applications, it delivers the robust performance and cost-efficiency your network demands.

Optical Test Equipment

The 10G SFP+ DAC 1M is often used in optical test equipment setups for testing and validating optical modules, transmission systems, and networking devices. The high data rate and stability of this DAC make it perfect for connecting test instruments and devices under test, ensuring accurate performance evaluation and minimizing downtime during system testing. This is particularly useful for manufacturers and service providers in the optical communications industry.

Automotive Networks

In automotive networks, the 10G SFP+ DAC 1M is utilized to connect various electronic control units (ECUs) within a vehicle. The DAC enables high-speed communication for systems such as autonomous driving, infotainment, and in-car networking, where low-latency, high-bandwidth communication is critical. This ensures smooth operation and communication between different vehicle subsystems, contributing to the development of smart and connected vehicles.

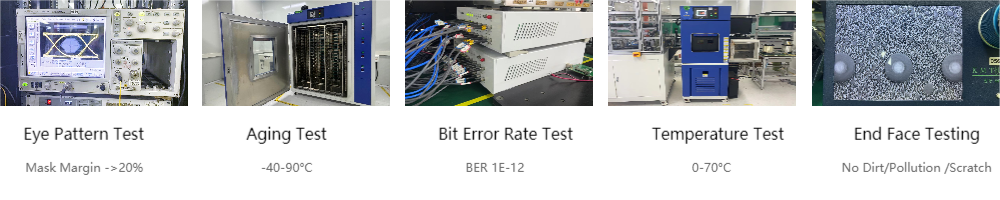

Rigorous Industrial Product Testing

ESOPTIC is equipped with a comprehensive range of professional testing equipment designed to assess various parameters of optical products.

This ensures the highest performance, quality, and stability of optical transmission in all of our products.

Product packaging specification

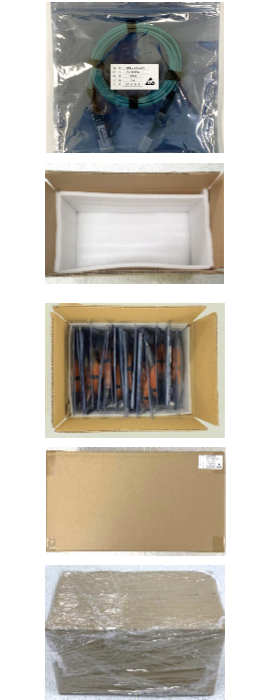

Packing of Direct Attach Copper products

Put DAC module into electrostatic bag (note module direction) and label.

The bottom, surface and side of the carton are filled with one piece of anti-static foam to protect the product.

According to the packing quantity requirements, put the products packed in anti-static ziplock bags into packaging cartons.

The space left in the trunk must be filled with anti-static foam to ensure that it will not be damaged in transit.

The outer case label is attached to the side position of the outer case.Label the outer case after sealing.

At the time of delivery, the entire outer box should be wrapped with at least 4 layers of wrapping film protection.

※The space in the box and the space in the mantissa box shall be filled with foam.